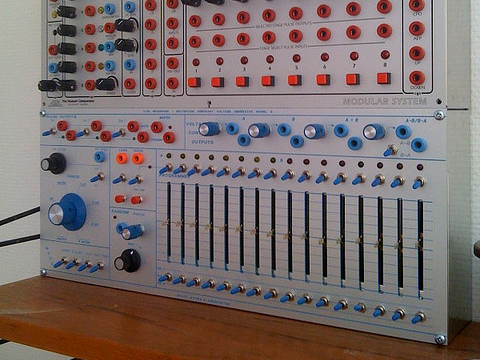

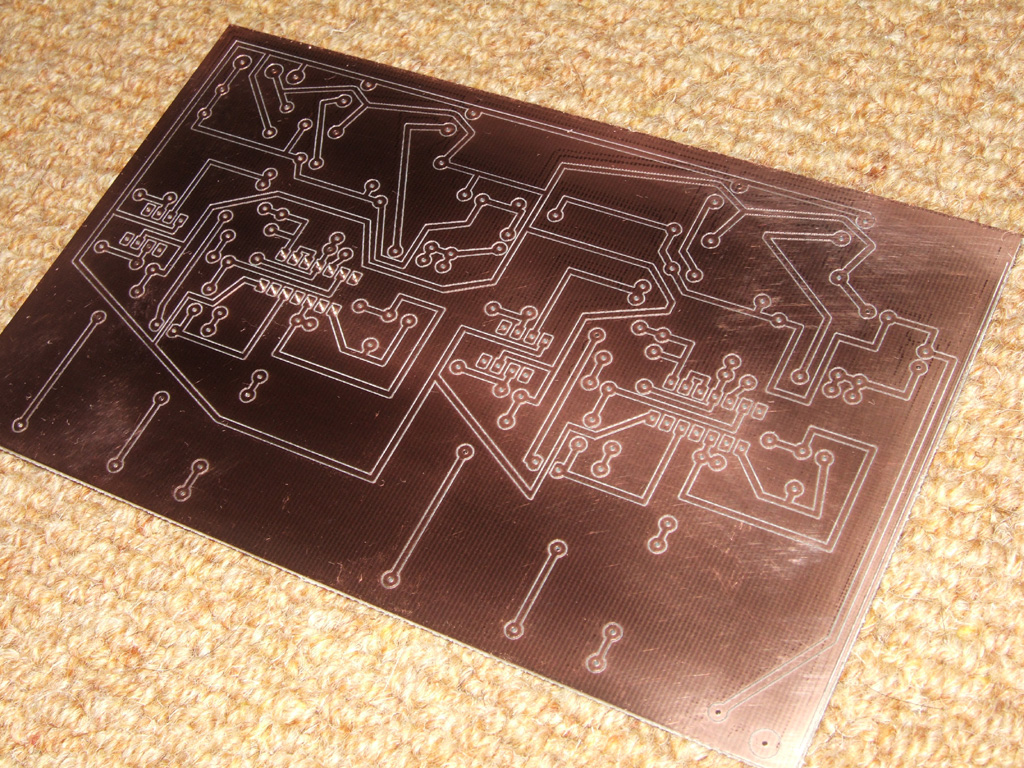

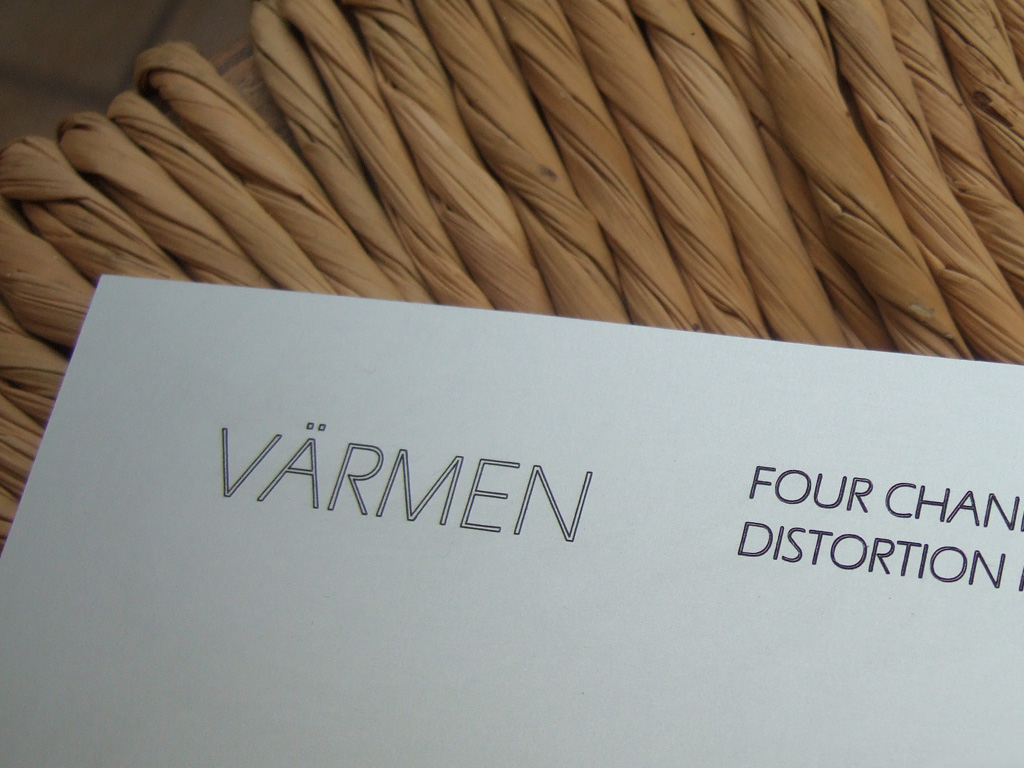

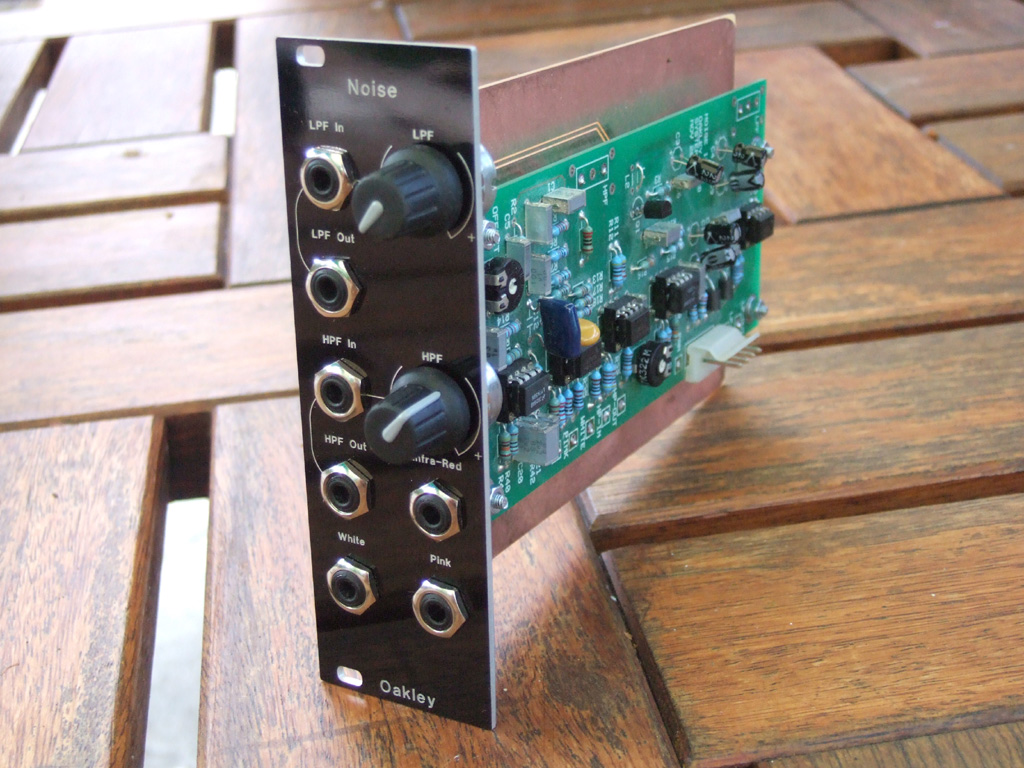

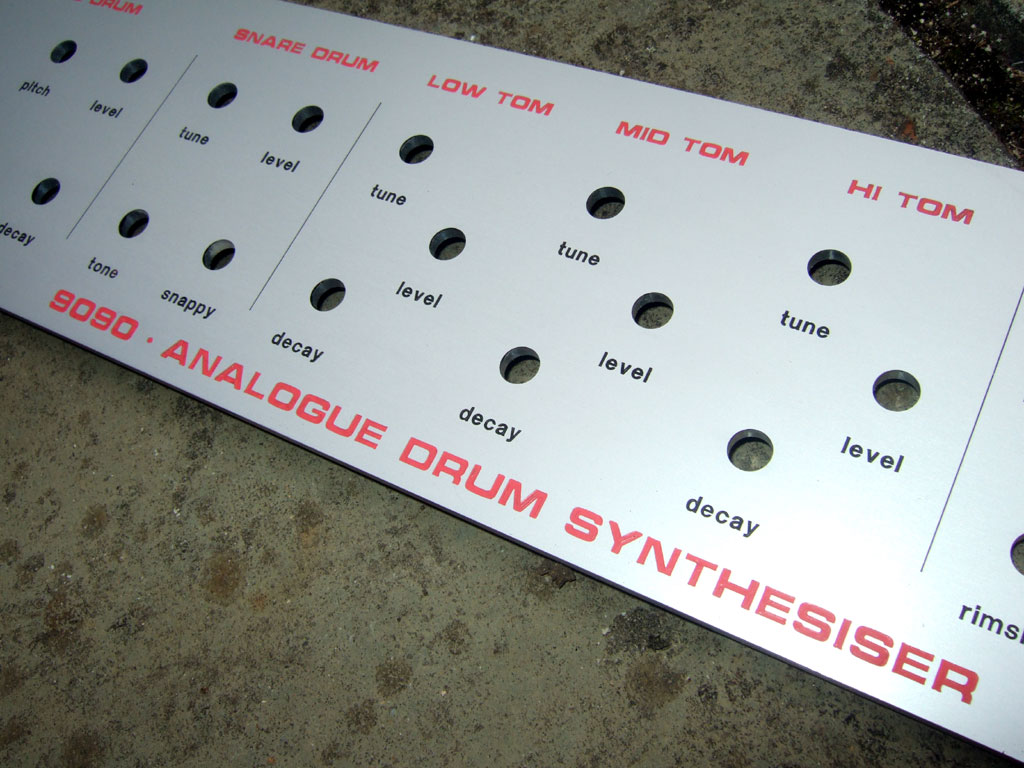

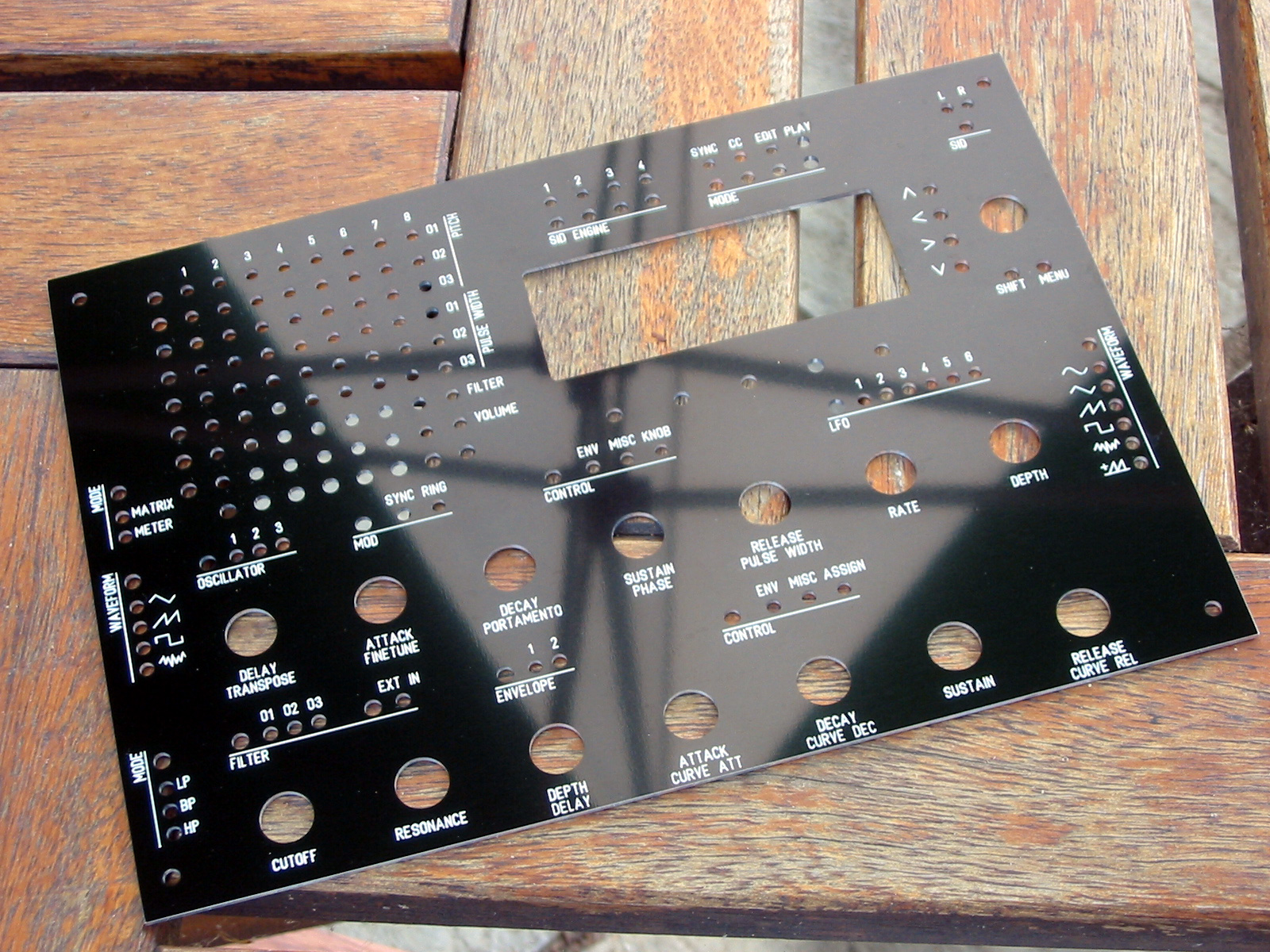

Shown here are selection of examples of CNC engraving, together with milling of profiles and apertures. Panels can be made from suitable files supplied by customer, or we offer an additional design service.

Common questions about panel engraving

What materials can be reliably engraved?

- Engraving is dependant on surface. Although pretty much anything can be engraved, for most work i would strongly recommend sticking to anodised aluminium (note: anodised is not the same as brushed, although brushed can also be anodised post-brushing)

- Anodised surfaces are available in different colours and finishes, matt black and satin being the most widely used. Other common colours include blue, red, gold, silver (natural), and dark green.

Do you supply the metal work, or do I have to send it in?

Can you work on material I send you?

- Material is generally supplied. Common thicknesses are 1.5mm, 2.0mm, and 3.0mm, with most common sizes / finished being kept in stock for minimal lead-times.

- I am also happy to work on customer supplied materials, providing they are anodised, and not brushed or powder-coated.

What file formats do you accept?

- The machine itself runs on g-code, which can be created from most vector formats. If you are working in a vector based graphic application, save off the files as .dxf format (in R12) but unfortunatly some graphics applications export non-standard dxf files. Customer specific advice can be given in this area.

- If you are working in a true CAD enviroment, just send over the R12 dxf files. If relevent / possible, put the engraving on a different layer to the milling / drilling

Can you quote me on my panel design?

- Because there are so many variables, its impossible to give anything other than very very rough ideas as to pricing without seeing some true CAD designs of what needs to be done.

- That said, small, un-drilled, modular panels normally work out at around the £20-25 mark. Complex multi-stroke engraving or routing of slider holes etc. might add around £10 to this price.